The cannabis industry is constantly evolving, and with change happening almost daily it requires equipment and process management systems that are continuously improving alongside it. Like the industry itself, Canncas it constantly looking for ways to stay on the cutting edge by evolving their product lines and making new, more efficient equipment for their customers.

The Canncas difference lies in their ability to adapt. They are consistently trying to push the envelope, and their team of engineering experts have a passion for helping their customers find the best solutions for their operation that can help to increase efficiencies in production.

Since opening their doors in August of 2018, Canncas has produced large quantities of stainless-steel equipment for the cannabis industry. They work tirelessly to satisfy the needs of each customer, whether it’s working with tight deadlines, customized sizing or unique requests.

With in-depth of experience helping clients to create layouts and floorplans depending on their production rates and facility size, Canncas takes the time to understand the process and production goals of each customer so they can design, manufacture and fabricate a customized solution that is unique to each case.

Canncas works with and ships to customers all over North America and Europe and all their products are proudly made in Canada with food grade stainless-steel construction to meet the industry’s high level of sanitation standards.

The premier drying solution provided in the industry

The premier drying solution provided in the industry

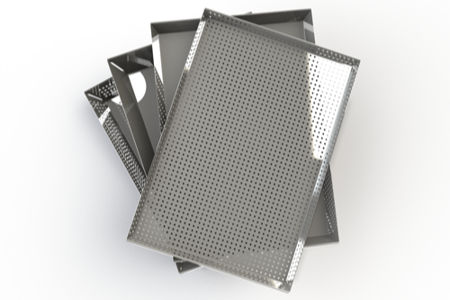

The Canncas drying rack and tray system is customizable in height, shelf spacing, and number of tiers and chambers based on each facilities’ requirements and process. The racks are designed to work with manual and automated pan loading and unloading system and come in multiple sizes and configurations including LED grow racks, hanging racks, drying racks and transportation racks. Customers can choose from a wide variety of caster options based on weight for ease of movement.

The drying trays are available in a multiple of perforated configurations to provide the optimal drying solutions. The series also includes solid matching trays located at the bottom of the racks to capture all product during the drying cycle. All trays are fully welded for durability and strength, come with an electro polished finish and are available in 18 or 20 gauge.

Innovative solutions

As warehouse facilities grow and the number of plants increase, the equipment to support each stage of the operation must also change to handle the influx of production. From this thought the Canncas Utility Wall was created as an innovative solution for the growing needs of an evolving industry.

The system is designed for grow racks to roll in and out with ease. When a rack of newly propagated plants is wheeled in, each rack level has access to its own LED lighting with full-cycle spectrum optimized for rapid growth and complete plant development, along with water irrigation and drainage. And for optimal plant health, each rack bay is equipped with air baffles to control air volume and direction of flow. Lighting, irrigation and air flow distribution can all be controlled from one central location.

Complete drying systems

Each Canncas Drying System comes equipped with a state-of-the-art advanced control system which allows the operator to set the preferred drying curve and repeat it time after time for a high quality and consistent product. The energy efficient systems result in lower operating costs and provide well distributed and consistent air circulation in the chamber resulting in the drying process being reduced. Drying systems can be designed and manufactured to accommodate all requirements from micro growers to commercial production facilities.

Full end to end solutions

Canncas always strives to produce top of the line, competitively priced and fit for purpose equipment by bringing its customers the most complete solution for any operation through better engineering, design and planning. If you are in search of improving your production utilizing smartly designed and engineered, long lasting, high quality equipment, please contact us today!

Read the article online in Health Europa Quarterly Oct 19th Issue 11. This article can be found on pages 108-109.

The premier drying solution provided in the industry

The premier drying solution provided in the industry